Optimizing Performance and Quality With Cutting-Edge Steel Stamping Approaches

In the realm of steel marking, the search of operational excellence with the assimilation of cutting-edge methods is critical. The crossway of innovative metal marking methodologies, automated systems, rigorous top quality controls, and lean manufacturing concepts supplies a tantalizing glance into the future of manufacturing.

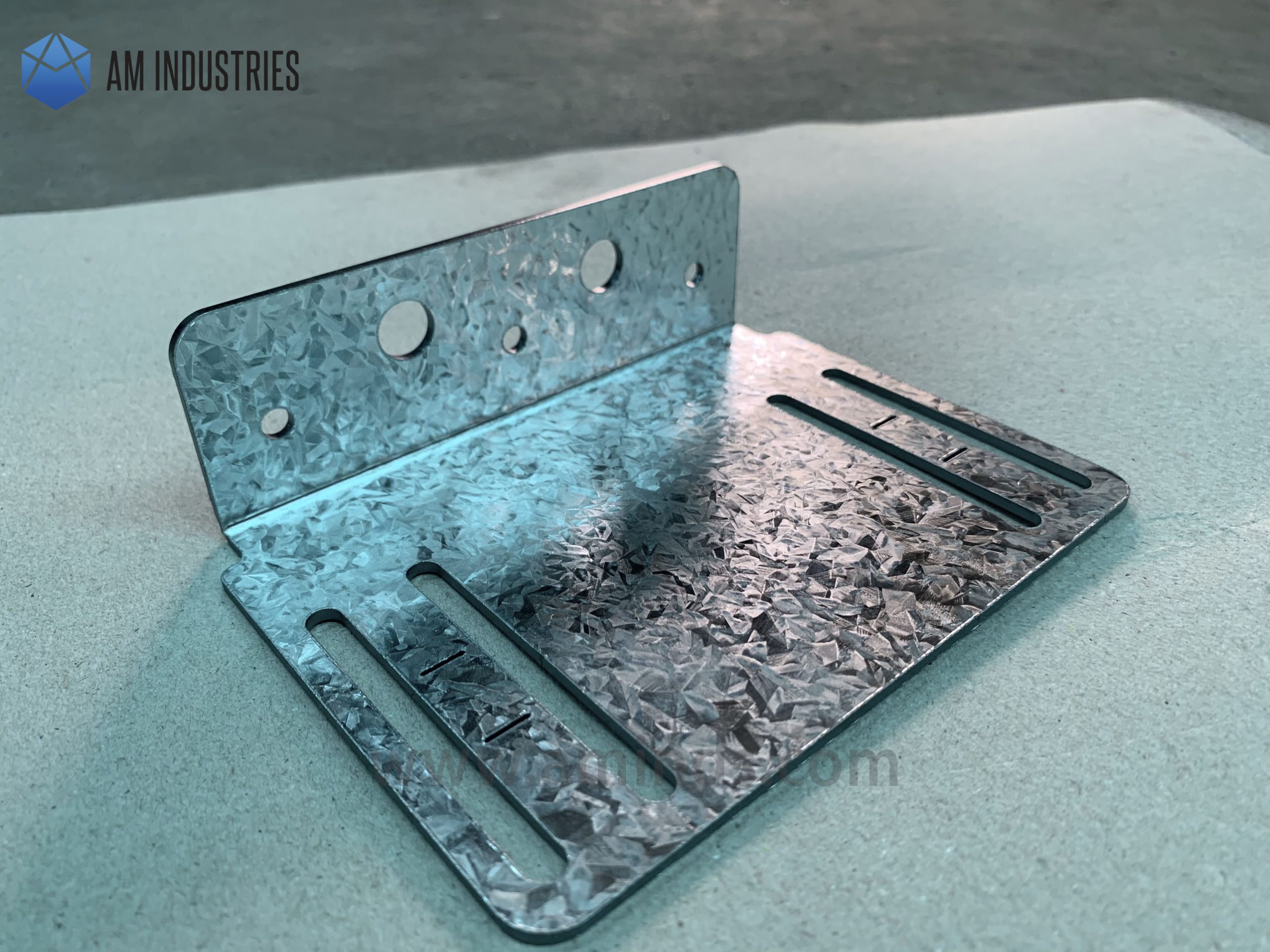

Advanced Steel Stamping Technologies

In the world of metal stamping, the combination of innovative technologies has transformed the market, improving accuracy and performance in manufacturing processes - Metal Stamping. Advanced steel stamping modern technologies have actually played a crucial duty in raising the capacities of manufacturers, enabling even more elaborate designs and higher manufacturing speeds

Among one of the most substantial innovations in steel marking technology is the execution of computer system numerical control (CNC) systems. CNC systems allow exact control over the stamping procedure, causing precise and constant manufacturing of complicated parts. Furthermore, making use of servo presses has caused improvements in energy efficiency and decreased cycle times, further enhancing the manufacturing procedure.

Additionally, the integration of automation and robotics has structured steel stamping operations by raising efficiency and decreasing the danger of mistakes. Automated systems can perform tasks with rate and precision, bring about enhanced overall effectiveness in the assembly line.

Automated Procedures for Efficiency

Use of automated procedures in metal stamping operations has actually dramatically improved effectiveness and performance in producing centers (Metal Stamping). Automated systems have actually revolutionized the metal stamping market by simplifying processes, minimizing manual intervention, and decreasing the margin of mistake. These automated solutions include a series of modern technologies, including robot arms, CNC machines, and digital control systems, that work cohesively to execute intricate marking tasks with precision and rate

One primary advantage of automated procedures in steel marking is the regular high quality they supply. By removing human mistake and variations in manufacturing, automated systems guarantee that each stamped part fulfills precise requirements with very little issues. Automation allows continuous procedure, dramatically lowering downtime for device modifications and upkeep, thereby making best use of total performance.

Furthermore, automated procedures improve security in steel stamping operations by lessening the requirement for hand-operated handling of sharp tools and heavy materials. This not just safeguards workers however also adds to an extra structured and reliable workflow. Finally, the combination of automated processes in metal stamping procedures is important for accomplishing optimal efficiency, top quality, and security criteria in modern production settings.

Quality Assurance Measures in Marking

Provided the focus on regular top quality and performance attained with automated procedures in metal marking operations, implementing durable top quality control measures comes to be critical to promote requirements and make sure accuracy in stamped components. Quality control in metal stamping entails a multi-faceted method to assure the integrity and precision of the end products. Assessment checkpoints at different stages of the stamping procedure are important to recognize any kind of deviations from requirements at an early stage. Making use of advanced modern technologies such as digital vision systems and automated measurement devices can improve the rate and precision of high quality inspections. Analytical process control methods assist in monitoring and managing the stamping process to detect any kind of variations that might affect top quality. Furthermore, training programs for staff on quality requirements and treatments are critical to ensure that every person entailed understands and follows the recognized quality assurance protocols. By incorporating these measures into steel navigate to this site stamping operations, suppliers can continually produce top quality stamped parts that fulfill the rigorous demands of modern sectors.

Enhancing Precision Via Advancement

To attain unmatched precision in metal marking processes, introducing developments are constantly being developed and integrated right into the production operations. Advanced modern technologies such as laser cutting systems and computer system mathematical control (CNC) machines have actually reinvented the method steel elements are marked with utmost precision. By making use of laser cutting technology, producers can achieve intricate and complex styles with micron-level precision, making sure that each stamped component meets the most strict top quality criteria.

Furthermore, making use of simulation software application enables makers to assess and maximize marking processes before actual production, recognizing potential locations for renovation and make improvements criteria to accomplish maximum accuracy. By welcoming these ingenious innovations, producers can enhance accuracy, rise effectiveness, and deliver high-grade stamped items that satisfy the most stringent needs of modern-day markets.

Executing Lean Manufacturing Practices

Including lean manufacturing methods right into metal stamping procedures can lead to streamlined production procedures and increased overall performance. By concentrating on eliminating waste, maximizing sources, and constantly enhancing procedures, metal stamping business can enhance efficiency and quality while minimizing prices.

Additionally, lean manufacturing practices encourage a society of continual improvement within the organization. By equipping staff members to identify and deal with inadequacies, firms can make step-by-step adjustments that lead to substantial efficiency gains in time. Applying devices such as Click Here five, Kanban systems, and value stream mapping can assist simplify procedures, reduce lead times, and enhance overall quality in metal stamping processes.

Conclusion

To conclude, the use of innovative steel marking innovations, automated procedures, quality assurance actions, technology for accuracy improvement, and execution of lean production methods are crucial for making best use of performance and quality in steel marking procedures. These techniques guarantee that products are produced with consistency, precision, and cost-effectiveness. By integrating these click here for more advanced techniques, manufacturers can remain affordable in the industry and fulfill the needs of clients successfully.

Given the emphasis on constant high quality and effectiveness attained via automated procedures in steel marking procedures, carrying out durable top quality control actions comes to be vital to maintain criteria and make certain accuracy in stamped components. Applying devices such as Five, Kanban systems, and worth stream mapping can assist enhance operations, minimize lead times, and improve general high quality in metal stamping procedures.

In conclusion, the application of innovative steel marking modern technologies, automated procedures, high quality control procedures, development for precision enhancement, and execution of lean production techniques are critical for making best use of performance and high quality in metal stamping operations.

Comments on “The Development of Metal Stamping Technology: A Comprehensive Review”